Thimble Pros features the voices of rock-star small businesses. In this post, Melanie Barrett, founder of Bailey Bug, discusses her journey to finding a mission-aligned clothing manufacturer, plus the top apparel-making tools that she always keeps nearby.

Founding an apparel company

I never thought I would be an entrepreneur, let alone a clothing designer: I was an opera performance major. I began making wheelchair capes for my sister, Bailey, when I was eight years old. Now, I create specialized apparel and accessories with warmth, style, and safety for those who use wheelchairs. I’m proud to work with a local manufacturing partner that gives a voice to individuals with disabilities.

Their mission is vital to the heart of my company. Bailey was born with Lennox-Gastaut Syndrome, a rare form of epilepsy. Although Bailey never spoke and couldn’t tell my family the name of her favorite animal, we chose a ladybug because she radiated love and joy. During her 20 years of life, Bailey taught so many people that it’s ok to be disabled. Her legacy lives on in the acts of goodness and accomplishment that she inspired in others. She is also the inspiration behind my company, Bailey Bug. My mission is to help spread the warmth Bailey gave my family and me to wheelchair users everywhere.

Melanie’s sister Bailey, who inspired her to create Bailey Bug.

When I decided to take my designs to the public, I entered and won Wittenberg University’s entrepreneurship competition called “Tiger Tank.” From there, I landed an internship with a product development team, D-Terra Solutions, in Powell, Ohio. When I was ready to start Bailey Bug, I found my first manufacturing partner. Unfortunately, I didn’t have any connection with them beyond the product we were making. I wanted to find a clothing manufacturer with a similar mission to my business.

Finding an apparel manufacturing match

My local Chamber of Commerce in Springfield, OH, connected me with The Abilities Connection (TAC). This organization employs makers with disabilities while providing them with personal rehabilitation services and vocational assistance. The organization gives its employees independence and self-confidence, and they have allowed me to bring Bailey Bug’s designs to life.

One aspect I love about working with TAC is the team’s adaptability. First, they provided me with my own office space, created a sewing room and assigned me a team of two sewers and a lead manager. I took the first cape that my former manufacturer made and showed it to the sewers to test the design. Now, we work on individual orders and B2B and bulk orders for sports teams, assisted living facilities, hospitals, and more. We put a personal touch on each product because the capes are so personal for our customers. For example, I don’t use a wholesale supplier. Instead, I go to Joann Fabrics and Crafts myself to pick out the flannel and fleece fabric for every order. My sewers can change the color of the binding and buttons and add embroidery.

Melanie in the TAC workshop.

Right now, we see the best outcome to growing our business through direct-to-consumer sales in different markets: high schools with adaptive classrooms and veterans in wheelchairs after being a part of the National Veteran’s Wheelchair Games this year in New York, NY. We are constantly innovating: We’re adding a D-ring to our capes so that people who don’t have full use of their fingers can put their coats on without assistance. We’re constantly changing as we go. And as the brand grows, TAC and I must stay connected. At the end of the day, we love working together.

My advice to clothing makers searching for a manufacturer is to find someone who fuels your passion. Small business owners get told “no” often, and being in a good environment with people you like is critical. It’s going to help you create better ideas, too. There are so many apparel companies out there. You will stand out if you find your voice, know what makes you feel good and find people to work with who make you feel good.

Melanie with a Bailey Bug client.

Bailey Bug’s top 10 apparel business tools

As a small apparel business, you may not be in a place where you can partner with a manufacturer just yet. Here are the tools that every startup clothing maker should have in their workshop. Remember to start with a small, simple toolbox and let your equipment grow with you because small steps lead to big victories:

- Tape measure: This was my very first equipment purchase. A tape measure for fabric is key. You have to mark exact inches and centimeters every time, so having multiple tape measures is helpful.

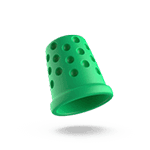

- Binder: Binding sticks the raw edges of fabric pieces together. A binder and a sewing machine are staples in TAC’s manufacturing process.

- Fabric pins and scissors: I order long fabric pins because we work with thick fabrics. I love brightly colored pins that help make my workday happy, which helps me get more done. Your fabric scissors should be able to withstand cutting multilayer fabric.

- Fabric markers: Fabric markers should be the right thickness, the right color — and most importantly, the ink should wash out when you’re done.

- Heavy-duty fabric thread: Have many extras of thread on hand! Thread breaks more often than you think, especially when working with thick fabric.

- Sewing machine: I use a Singer Heavy Duty at home, but we use manufacturing-grade machines at the TAC facility. Some apparel makers recommend using a serger, but I find that my sewing machine is enough for my needs.

- Design software: I use Canva. Photoshop is hard to use, it’s expensive, and many people don’t have excellent Photoshop knowledge. On the other hand, Canva is easy to use to make colorful, on-brand designs. I used it to start a business by myself without help from a marketing team. I can create images and post them to social media and other marketing channels.

- Accounting software: I prefer Quickbooks for creating and sending invoices.

- A savings account: This is your secret weapon for buying the equipment you need. I use Digit, which costs $3.99 per month. It takes a little bit of money out of your checking account and towards your savings goals (in my case, for business expenses). As a small business owner, it’s crucial to grow a savings account without taking too much money out of your checking; in short, to save without realizing you’re saving.

- An embroidery machine: Right now, I send my capes out to a third party for embroidery, but I would love to have an embroidery machine. Because I’ve been saving, I am getting one in January!

Follow Melanie on Facebook @Baileybugllc, Instagram @Baileybugllc_ and Twitter @BaileyBug2